Amid the fierce competition in the surging new energy vehicle (NEV) market, where major automakers are locked in an intense battle, Xiaomi’s highly anticipated first car model—the Xiaomi SU7—finally hit the consumer market in late March this year, marking its official entry into this cutthroat industry showdown.As the second major player after Huawei to make a genuine transition from the 3C (computer, communication, and consumer electronics) sector into automotive manufacturing, Xiaomi has delivered a vehicle that showcases distinct innovations, setting it apart from traditional automakers.

As a flagship smart electric vehicle representing the future of autonomous driving, the Xiaomi SU7 is inevitably designed with Level 5 (L5) full self-driving capabilities in mind. This makes an intelligent brake-by-wire system a mandatory standard feature. However, industry experts have noticed that instead of adopting the mainstream 1Box brake-by-wire system currently dominating the market, Xiaomi has opted for what appears to be a two-box system—a configuration often associated with older-generation technology.Yet, this implementation differs from the conventional iBooster + EPS (HEV) two-box setup, sparking widespread speculation among self-proclaimed industry pundits. Misleading interpretations have clouded public understanding, with some Shanghai-based two-box startups even claiming that their “outdated” two-box technology is the future of autonomous driving.

To dispel the confusion and provide a clear understanding of this next-generation two-box brake-by-wire system, let us—like magicians—slowly unveil the mysteries behind its design.

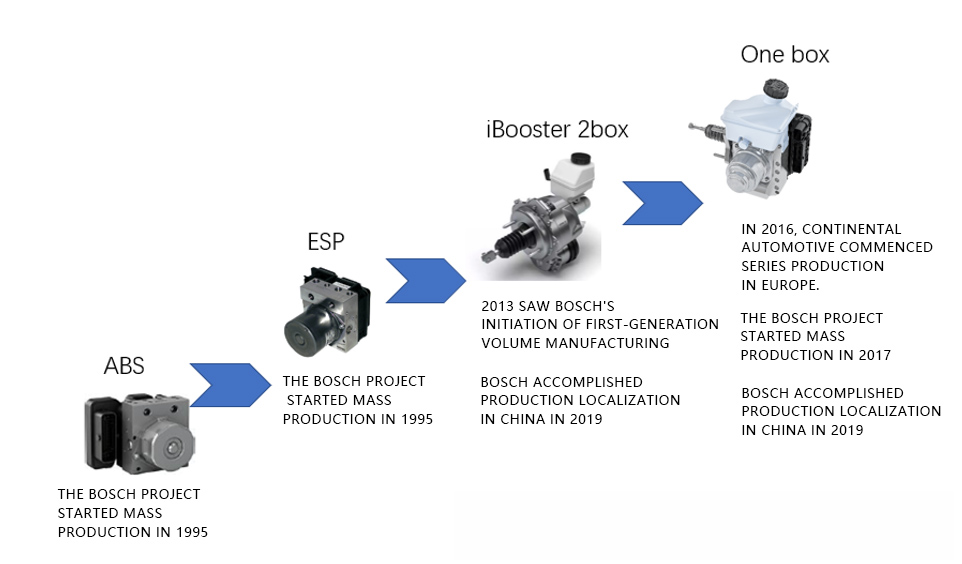

The evolution of brake-by-wire systems has progressed from early technologies like ABS and ESP, through first and second generation two-box systems, to today’s mainstream one-box solutions. In this field, Germany’s Bosch has long maintained a position of global technological leadership.In recent years, with the strong market demand for brake-by-wire products driven by autonomous driving development, numerous Chinese companies – both listed enterprises and startups – have begun emulating Bosch’s products. Notably, for its SU7 model, Xiaomi has chosen to collaborate with Bosch, becoming the first in the world to implement their third-generation two-box system.

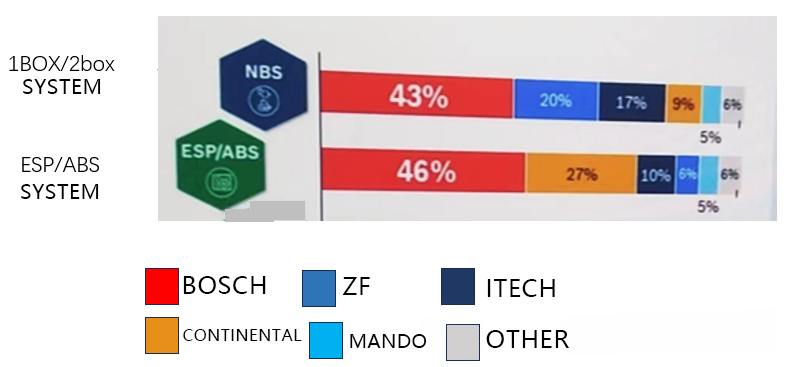

During this dynamic interplay of collaboration and competition, Xiaomi sought to balance its supplier relationships and curb Bosch’s pricing power by exploring a partnership with a Ningbo-based company as a secondary brake system supplier. However, after evaluating its technical capabilities, the Ningbo firm recommended against supplying the initial batch, advising Xiaomi to prioritize the successful launch and quality reputation of its debut model by sticking with Bosch’s proven solution. This decision underscores Bosch’s industry-leading reputation for safety and reliability in brake-by-wire systems.Current global market share data further reinforces Bosch’s dominance: the German supplier holds 43% of the combined 1Box and 2Box market, followed by ZF (20%) and Continental (9%).

The third-generation two-box system fundamentally differs from the second-generation solution in both technological approach and product architecture philosophy. The first and second-generation two-box systems were developed as an architectural platform primarily to meet the requirements of pure electric vehicles, essentially representing a transitional product derived from adapting internal combustion engine platforms for electrification. As such, electromechanical brake assist and regenerative braking constituted the core functionalities of these earlier generations.

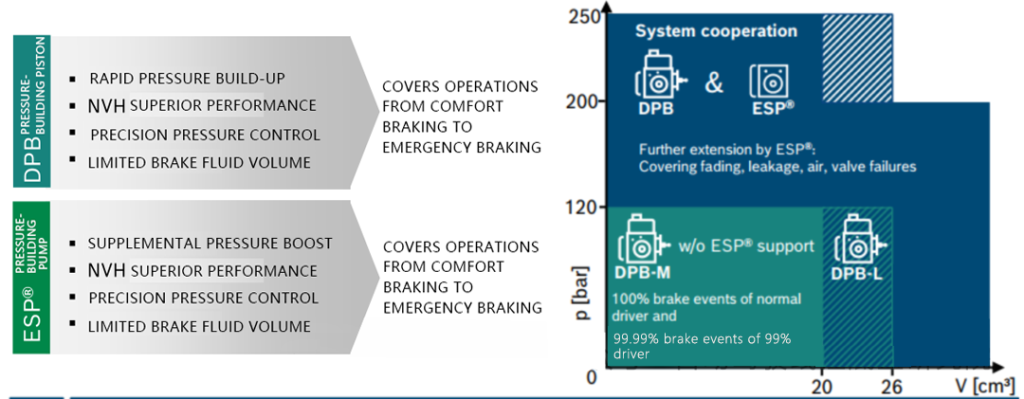

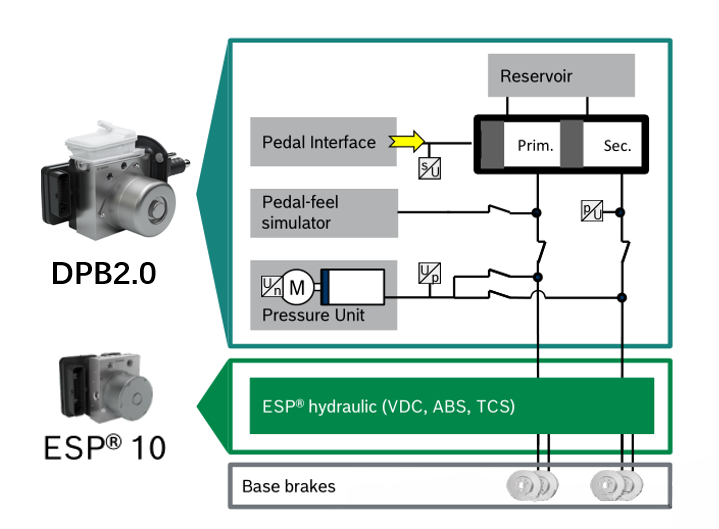

In contrast, the third-generation two-box system, comprising DPB 2.0 (Dual-Piston Brake) and ESP 10 (Electronic Stability Program), represents an entirely new platform specifically designed for future fully autonomous driving applications. This next-generation system features intelligent operation and comprehensive safety redundancy as its key characteristics, establishing it as a truly fully-decoupled brake-by-wire system. Every component’s design lifespan and software control mechanisms are specifically configured to meet the long-term technical requirements of autonomous driving operations.

The third-generation architecture marks a complete departure from previous solutions, as it is the first braking system designed from the ground up for autonomous vehicle applications rather than being adapted from legacy platforms. This system-level innovation reflects the automotive industry’s transition toward autonomous-native designs that prioritize fail-safe operation, extended durability, and intelligent control capabilities required for L4/L5 autonomous driving scenarios.

DPB – Decoupled Power Brake 2.0 (Decoupled Power Braking System Version 2.0)

- The decoupled braking redundancy solution meets the higher demands of future autonomous driving.

The most robust fail-safe solution

- Achieving four-wheel braking assistance in single-fault scenarios through hydraulic backup

Easier installation with dynamic control module independently mounted from the firewall

- Enhanced installation flexibility with improved NVH performance

Multi-version pressure-generation module designs cover diverse braking dynamic performance requirements

Covers diverse vehicle applications from passenger cars to heavy-duty trucks

Pedal decoupling enables highly efficient regenerative braking

Adjustable pedal feel to meet diverse customer requirements

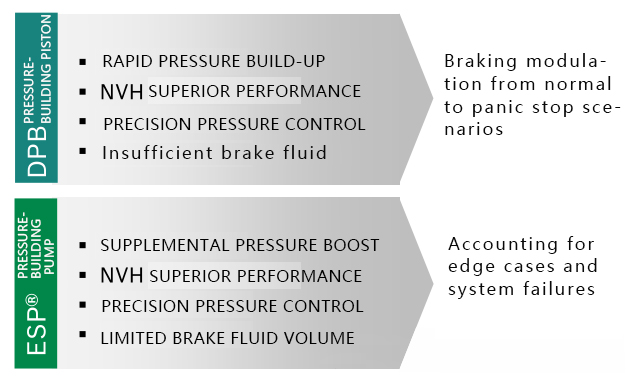

- Leveraging the design advantages of both DPB pressure-building pistons and ESP pressure pumps to optimally allocate system functions; supports parking redundancy.

- Scalable functionality through multiple ECU and µC configurations

Supports diverse system requirements: functional safety, remote firmware updates, pedal wake-up, parking redundancy, and more.

Key Benefits of the Fail-Safe Strategy:

- Braking Redundancy Enhanced Fail-Safe Protection

- JAMA Fail-Operational Backup Requirement (0.4g deceleration @ 200N pedal force)

- Light/Heavy-Duty Truck

- New Energy Vehicle

- Achieve seamless transition in unexpected system failure scenarios

MC offers greater dimensional flexibility

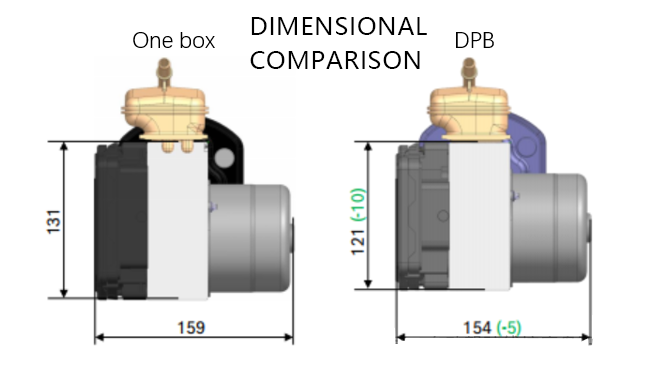

The Xiaomi SU7 has garnered widespread acclaim from owners since its launch, becoming a highly sought-after model among Mi fans. Particularly noteworthy is its fully decoupled intelligent brake-by-wire system 2.0 – DPB (Decoupled Power Brake), which significantly enhances the vehicle’s driving performance. When combined with advanced autonomous driving capabilities, the system creates a perfect synergy.This system was custom-developed for Xiaomi by Bosch and comes as standard equipment across all trim levels. With its compact and space-saving design, it offers distinct advantages over conventional one-box solutions currently available in the market.As of now, apart from Bosch, no other global players—including Continental, ZF, Mando, or other domestic/international manufacturers—have successfully developed a comparable product, giving Xiaomi a significant technological lead.

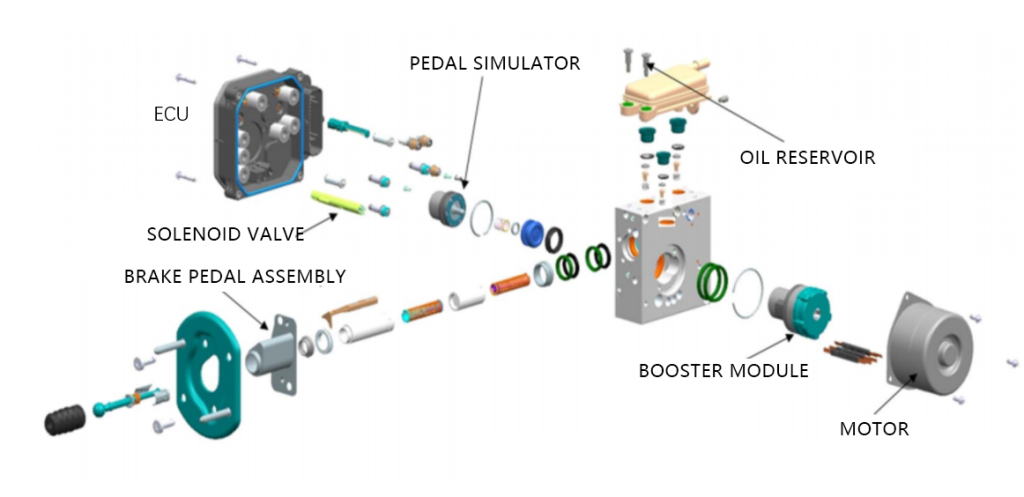

The main components of the product are as follows:1.Electronic Control Unit and Software (ECU) 2.Hydraulic Integrated Valve Block 3.Solenoid Valve4.Brake Pedal Simulator5.Oil Reservoir6.Motor7.Pedal Simulator

In simple terms, the system works as follows: When the driver presses the brake pedal, the pedal simulator provides realistic force feedback to mimic traditional braking feel. Simultaneously, pedal travel sensors detect the driver’s braking intent and transmit the data to the central ECU. The ECU calculates the required braking force, activates the actuation motor, and drives the booster module to generate high-pressure brake fluid to the wheels—decelerating or stopping the vehicle.

Critically, this process features full decoupling between the driver’s input and hydraulic pressure output. The electromechanical system eliminates mutual interference, achieving genuine by-wire braking with superior comfort.

DPB2.0: Lighter, smaller, and easier to install

When combined with ESP10, it can achieve higher safety requirements for L4 and L5 autonomous driving.

The two can serve as mutual redundancies, offering performance and reliability unmatched by traditional iBoosters. This new-generation 2-box architecture represents true mutual backup, meeting regulatory requirements for system safety.